Nissan Maxima Service and Repair Manual: P2135 TP sensor

Description

Electric throttle control actuator consists of throttle control motor, throttle position sensor, etc. The throttle position sensor responds to the throttle valve movement.

The throttle position sensor has two sensors. These sensors are a kind of potentiometers which transform the throttle valve position into output voltage, and emit the voltage signal to the ECM. In addition, these sensors detect the opening and closing speed of the throttle valve and feed the voltage signals to the ECM. The ECM judges the current opening angle of the throttle valve from these signals and the ECM controls the throttle control motor to make the throttle valve opening angle properly in response to driving condition.

DTC Logic

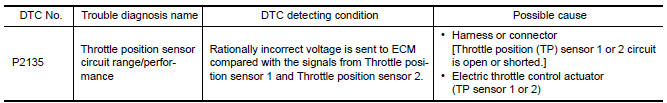

DTC DETECTION LOGIC

NOTE: If DTC P2135 is displayed with DTC P0643, first perform the trouble diagnosis for DTC P0643. Refer to EC-394, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION: Before performing the following procedure, confirm that battery voltage is more than 8 V at idle.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Start engine and let it idle for 1 second.

- Check DTC.

Diagnosis Procedure

1.CHECK GROUND CONNECTION

- Turn ignition switch OFF.

- Check ground connection E9.

2.CHECK THROTTLE POSITION SENSOR POWER SUPPLY CIRCUIT-I

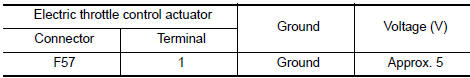

- Disconnect electric throttle control actuator harness connector.

- Turn ignition switch ON.

- Check the voltage between electric throttle control actuator harness connector and ground.

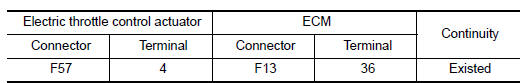

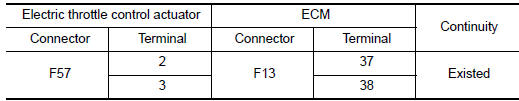

3.CHECK THROTTLE POSITION SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between electric throttle control actuator harness connector and ECM harness connector.

- Also check harness for short to ground and short to power.

4.CHECK THROTTLE POSITION SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

- Check the continuity between electric throttle control actuator harness connector and ECM harness connector.

- Also check harness for short to ground and short to power.

5.CHECK THROTTLE POSITION SENSOR

6.REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

- Replace electric throttle control actuator

7.CHECK INTERMITTENT INCIDENT

Component Inspection

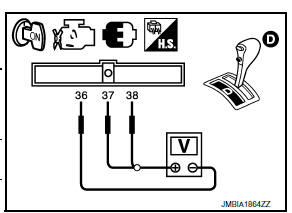

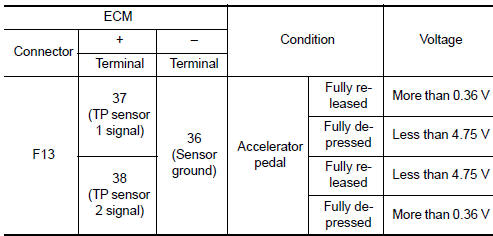

1.CHECK THROTTLE POSITION SENSOR

- Turn ignition switch OFF.

- Reconnect all harness connectors disconnected.

- Perform EC-476, "Special Repair Requirement".

- Turn ignition switch ON.

- Set selector lever to D position.

- Check the voltage between ECM harness connector terminals under the following conditions.

2.REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

- Replace electric throttle control actuator

Special Repair Requirement

1.PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

2.PERFORM IDLE AIR VOLUME LEARNING

P2127, P2128 APP sensor

P2127, P2128 APP sensor

Description

The accelerator pedal position sensor is installed on the upper end

of the accelerator pedal assembly. The sensor detects the accelerator

position and sends a signal to the ECM.

...

P2138 APP sensor

P2138 APP sensor

Description

The accelerator pedal position sensor is installed on the upper end

of the accelerator pedal assembly. The sensor detects the accelerator

position and sends a signal to the ECM.

Ac ...

Other materials:

Navigation Swipe to Meter

Turn-by-turn route guidance can also be viewed

in the vehicle information display by using Navigation

Swipe to Meter. This can be done by

programming a route, touching the turn-by-turn

route icon on the center display, and swiping

towards the general direction of the vehicle information

di ...

Windows

Power windows

WARNING

Make sure that all passengers have

their hands, etc. inside the vehicle while

it is in motion and before closing the

windows. Use the window lock switch to

prevent unexpected use of the power

windows.

To help avoid risk of injury or death

through unintended o ...

High-mounted stop lamp

Exploded View

High-mounted stop lamp cover

High-mounted stop lamp bulb

Removal and Installation

REMOVAL

Slide the high-mounted stop lamp rearward on the parcel shelf to

give clearance to the front locking tabs.

Lift the front of the high-mounted stop lamp up and slide it forward ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0062