Nissan Maxima Service and Repair Manual: Parking brake shoe

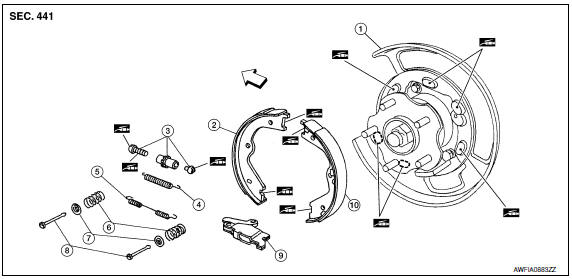

Exploded View

- Back plate

- Parking brake shoe (front)

- Adjuster

- Adjuster spring

- Return spring

- Anti-rattle spring

- Retainer

- Anti-rattle pin

- Toggle lever

- Parking brake shoe (rear)

Front

Front

Apply PBC (Poly Butyl Cuprysil)

grease or silicone based grease

Apply PBC (Poly Butyl Cuprysil)

grease or silicone based grease

Removal and Installation

REMOVAL

WARNING:

- Clean brakes with a vacuum dust collector to minimize the hazard of air borne particles or other materials.

- Clean dust on disc rotor and back plate using a vacuum dust collector. Do not blow with compressed air.

- Remove rear wheel and tire using power tool. Refer to WT-60, "Adjustment".

- Remove brake caliper torque member bolts, leaving brake hose attached, reposition the caliper aside with wire. Refer to BR-36, "Exploded View of Brake Caliper".

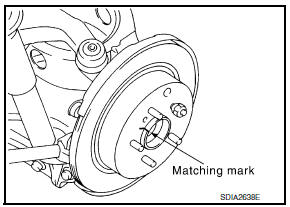

- With the parking brake pedal in the fully released position, remove the disc rotor. CAUTION: Put matching marks on both disc rotor and wheel hub when removing disc rotor. If the disc rotor cannot be removed, remove as follows:

- Secure the disc rotor in place with wheel nuts and remove adjuster hole plug.

- Rotate adjuster (1) in direction (B) to retract and loosen brake shoe, using suitable tool as shown.

- Remove anti-rattle pins, retainers, anti-rattle springs, return spring and adjuster spring.

- Remove parking brake shoes, adjuster assembly, and toggle lever.

INSPECTION AFTER REMOVAL

Lining Thickness Inspection

- Check thickness of lining.

Standard thickness (new) (A) : Refer to PB-11, "Parking

Drum Brake".

Wear limit thickness (A) : Refer to PB-11, "Parking

Drum Brake".

Disc Rotor Inner Diameter Inspection

- Check inner diameter of drum (in disc).

Standard inner diameter (new) : Refer to PB-11, "Parking

Drum Brake".

Wear limit of inner diameter : Refer to PB-11, "Parking

Drum Brake".

Other Inspections

- Check the following:

- Lining for excessive wear, damage, and peeling.

- Shoe sliding surface for excessive wear and damage.

- Anti-rattle pin for excessive wear and corrosion.

- Return spring and adjuster spring for sagging.

- Make sure that adjuster moves smoothly.

- Visually check the inside of drum for excessive wear, cracks, and damage.

- Replace with new parts as necessary.

INSTALLATION

Installation is in the reverse order of removal.

- Refer to PB-8, "Exploded View" and apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease to the specified points during installation.

- Assemble adjusters so that threaded part is expanded when rotating it in the direction as shown.

- Shorten adjuster by rotating it the opposite as shown

- Check parking brake shoe sliding surface and drum inner surface for grease. Wipe off all grease adhering to the friction surfaces.

ADJUSTMENT

After replacing the parking brake shoes or disc rotors, or if the parking brake does not function properly, perform the break-in operation as follows.

- Adjust parking brake pedal stroke to the specified amount. Refer to PB-4, "On-Vehicle Service".

- Perform parking brake break-in (drag run) operation by driving and performing the following steps:

- Drive forward at a constant speed of approximately 40 km/h (25 mph).

- Apply the parking brake for approximately 5 - 15 seconds at an operating force of approximately 150 - 199 N (15 - 20 kg, 34 - 45 lb).

CAUTION:

- To prevent lining from getting too hot, allow cool off period of approximately 5 minutes after every break-in operation.

- Do not perform excessive break-in operations, because it may cause uneven or early wear of lining.

- After break-in operation, check that the parking brake pedal stroke is at specification and adjust again as necessary. Refer to PB-4, "On-Vehicle Service".

Parking brake control

Parking brake control

Exploded View

Parking brake pedal

Parking brake switch

Pedal pad

Adjusting nut

Lock plate

Front cable

Rear cable (RH)

Rear cable (LH)

Equalizer

Spring

Pin

...

Service data and specifications (SDS)

Service data and specifications (SDS)

Parking Brake Control

Parking Drum Brake

...

Other materials:

Canceling a remote start

To cancel a remote start, perform one of the

following:

Aim the Intelligent Key at the vehicle and

press until the parking lights

turn off.

Turn on the hazard warning flashers.

Cycle the ignition switch ON and then OFF.

The extended engine run time has expired.

The first 10 minute ...

Inspection and adjustment

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : Description

Initial setting is necessary when battery terminal is removed.

CAUTION:

The following specified operations are not performed under the

non-initialized condition. ...

P0710 transmission fluid temperature sensor A

Description

The CVT fluid temperature sensor detects the CVT fluid temperature and sends

a signal to the TCM.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION: Always drive vehicle at a safe speed.

NOTE: Immediately after performing any "DTC CONFIRMATION

PROCEDURE", alway ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0071