Nissan Maxima Service and Repair Manual: Removal and installation

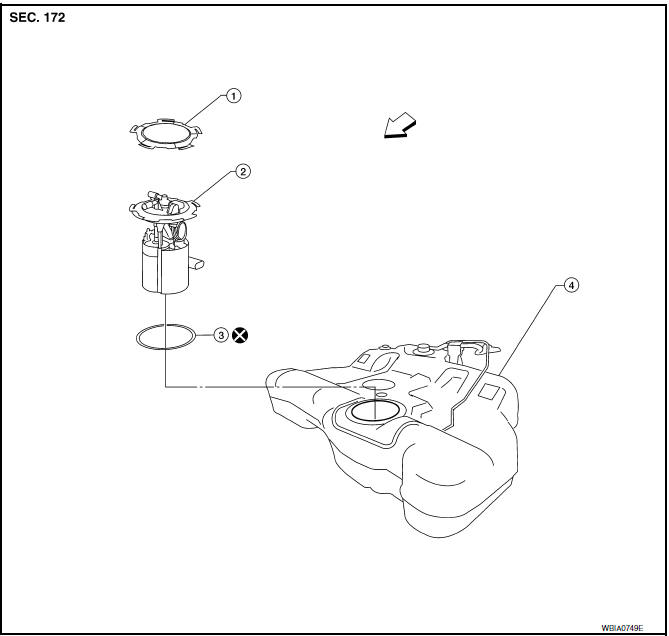

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

Exploded View

- Lock ring

- Fuel level sensor, fuel filter and fuel pump assembly

- O-ring

- Fuel tank

Front

Front

Removal and Installation

WARNING: Read "General Precautions" before working on the fuel system. Refer to GI-27, "General Precautions".

NOTE: When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

REMOVAL

- Unscrew the fuel filler cap to release the pressure inside the fuel tank.

- Release the fuel pressure from the fuel lines. Refer to EC-592, "Inspection".

- Disconnect the battery negative terminal.

- Remove the rear seat cushion. Refer to SE-70, "Removal and Installation" (with fixed seatback, WITH CLIMATE CONTROLLED SEATS), SE-73, "Removal and Installation" (with split seatback, WITH CLIMATE CONTROLLED SEATS), SE-128, "Removal and Installation" (with fixed seatback, W/O CLIMATE CONTROLLED SEATS) SE-131, "Removal and Installation" (with split seatback, W/O CLIMATE CONTROLLED SEATS).

- Turn the four retainers 90 degrees in a clockwise direction and remove the fuel pump inspection hole cover.

- Disconnect the fuel level sensor, fuel filter, and fuel pump assembly harness connector, EVAP hose quick connector, and the fuel feed hose quick connector from the fuel level sensor unit, fuel filter, and fuel pump assembly.

Remove the quick connector as follows:

- Hold the sides of the connector, push in tabs and pull out the tube.

- If the connector and the tube are stuck together, push and pull several times until they start to move. Then disconnect them by pulling.

CAUTION:

- The tube can be removed when the tabs are completely depressed. Do not twist it more than necessary.

- Do not use any tools to remove the quick connector.

- Keep the resin tube away from heat. Be especially careful when welding near the tube.

- Prevent acid liquid such as battery electrolyte, etc. from getting on the resin tube.

- Do not bend or twist the tube during installation and removal.

- Only when the tube is replaced, remove the remaining retainer on the tube or fuel level sensor, fuel filter, and fuel pump assembly.

- When the tube or fuel level sensor, fuel filter, and fuel pump assembly is replaced, also replace the retainer with a new one (green colored retainer).

- To keep the connecting portion clean and to avoid damage and foreign materials, cover them completely with plastic bags or something similar.

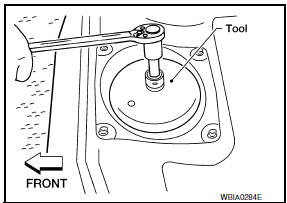

- Remove the lock ring using a socket drive handle and Tool as shown.

Tool number : KV991J0090 (J-46214) (shown)

: KV101207S0 ( - )

CAUTION: Discard the lock ring if damaged or distorted.

- Remove the fuel level sensor, fuel filter, and fuel pump assembly and O-ring. Discard the O-ring.

CAUTION:

- Do not bend the float arm during removal.

- Do not reuse the O-ring.

INSPECTION AFTER REMOVAL

Inspect the fuel level sensor, fuel filter, and fuel pump for any defects and foreign materials. Replace as necessary.

INSTALLATION

Installation is in the reverse order of removal.

- Install the fuel level sensor, fuel filter, and fuel pump assembly with the fuel feed hose facing the front of the vehicle as shown. Use a new O-ring.

CAUTION: Do not reuse O-ring.

- Connect the quick connector as follows:

- Check the connection for damage or any foreign materials.

- Align the connector with the tube, then insert the connector straight into the tube until a click is heard.

- After the tube is connected, make sure the connection is secure by performing the following checks:

- Pull the tube and the connector to make sure they are securely connected.

- Visually confirm that the two retainer tabs are connected to the quick connector.

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leaks.

- Turn the ignition switch to ON (without starting the engine) to apply fuel pressure to the fuel system, then check the connections for fuel leaks.

- Start the engine and let it idle and check for fuel leaks at the fuel system connections.

Periodic maintenance

Periodic maintenance

FUEL SYSTEM

Inspection

Inspect fuel lines, fuel filler cap and fuel tank for improper attachment,

leaks, cracks, damage, loose connections, chafing or deterioration.

If

necessary, repair or r ...

Fuel tank

Fuel tank

Exploded View

Fuel filler cap

Grommet

Fuel filler tube

Fuel tank

Fuel filler hose

Fuel tank protector

Fuel tank mounting straps

O-ring

&nb ...

Other materials:

Replacement operations

Description

This section is prepared for technicians who have attained a high level of

skill and experience in repairing collision-

damaged vehicles and also use modern service tools and equipment. Persons

unfamiliar with body

repair techniques should not attempt to repair collision-damaged ...

Main line between DLC and HVAC circuit

Diagnosis Procedure

1.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

Turn the ignition switch OFF.

Disconnect the battery cable from the negative terminal.

Disconnect the following harness connectors.

ECM

A/C auto amp.

Check the continuity between the data link connector and the A/C ...

Front fog lamp

Exploded View

Front bumper fascia

Front fog lamp

Front fog lamp bracket

Clip

Spring nuts

Removal and Installation

FRONT FOG LAMP

Removal

Remove the front bumper fascia. Refer to EXT-16, "Removal and

Installation".

Disconnect the harness connector from the fog lamp.

R ...

Nissan Maxima Owners Manual

- Illustrated table of contents

- Safety-Seats, seat belts and supplemental restraint system

- Instruments and controls

- Pre-driving checks and adjustments

- Monitor, climate, audio, phone and voice recognition systems

- Starting and driving

- In case of emergency

- Appearance and care

- Do-it-yourself

- Maintenance and schedules

- Technical and consumer information

Nissan Maxima Service and Repair Manual

0.0059